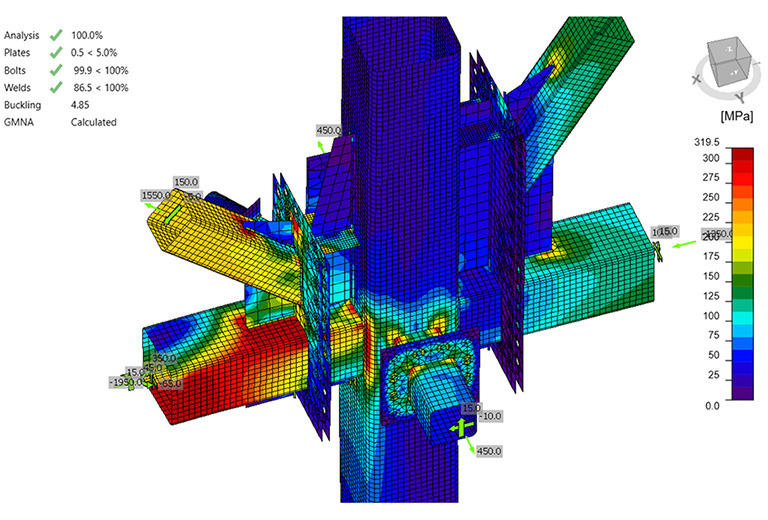

FEA

Finite Element Analysis

Discover the wide range of comprehensive FEA services offered by MOOR.

RBI

RISK BASED INSPECTION SERVICES [API 580]

Risk-Based Inspection (RBI) is a methodology that involves quantitative assessment of the probability of failure and the consequence of failure associated with each equipment item in an operation. An RBI program places individual pieces of equipment into specific categories based on their risks and prioritizes inspection efforts based on this categorization.

RBI is used to identify and understand incumbent risk drivers and therefore prioritize inspection-related activities. By taking a prioritized approach more focus can be given to high risk equipment and less focus to low risk equipment thereby increasing overall reliability and reducing costs both in terms of NDT inspection and also in potential equipment failures. An RBI inspection plan outlines the type and schedule of inspection for the assets in a production facility.

MOOR has many years of experience in providing Risk Based Inspection programs integrated with MOOR proprietary inspection

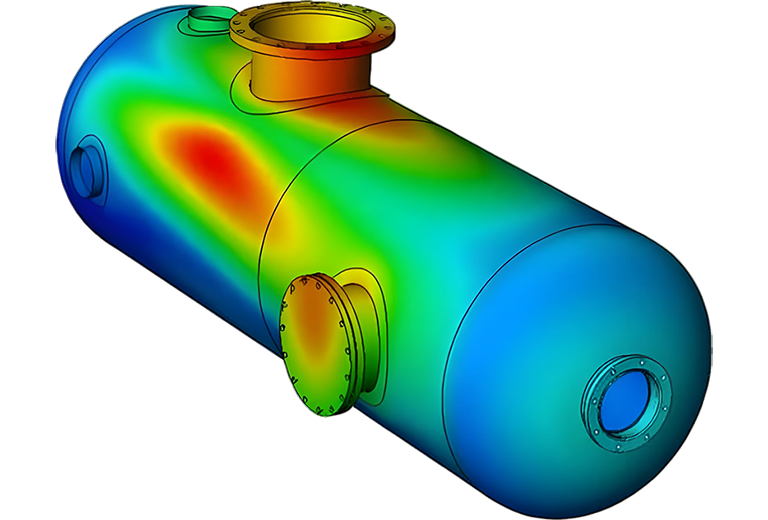

FFS API 579/ASME FFS-1

Fitness For Service

With a comprehensive fitness-for-service (FFS) assessment software tool for evaluating the integrity of ageing pipework, pipelines, storage tanks, boilers, pressure vessels and high temperature equipment, we pride ourselves as the sole service provider in the region

FFS covers pressure equipment against different damage mechanisms such as general and local metal loss, pitting corrosion, blisters, hydrogen damage, dents, gouges and laminations. In addition, the system provides evaluation techniques for assessing resistance to brittle fracture..

Down Hole Tools

Standard Drill String & Bottom Hole Assemblies

In addition to the several inspection techniques for drilling tubulars and the various tubing work strings, the rotary bottom hole assemblies, completion running tools as well as the different service tools and equipment require regulars inspection. MOOR offers the end user either at MOOR Base, or client's location, the following service lines:

- BHA inspection & Non-magnetic BHA equipment

- Full dimensional checks

- Visual Testing including internal video or optical

- Rotary Shoulder Refacing

LOLER INSPECTION

Lifting Inspection

If you own, operate or have control of lifting equipment, you have a legal duty under the Lifting Operations and Lifting Equipment Regulations (LOLER), to ensure that the equipment is safe to use and properly maintained.

MOOR provides inspection and certification packages on a wide range of lifting gear and lifting appliances for the onshore and offshore energy sectors. Our qualified inspectors are multi-disciplined, ensuring a fast and efficient service without interruption to operations.

Inspection packages can be carried out in-line with any pre-agreed international standards, e.g. LOLER, British, ASME, API, along with any client specific standards or requirements.